HISTORY95 - Plastics Forever

This blog is about the fascinating history of plastics.

After an introduction, I will

cover the first semi-synthetic (based on natural substances) plastics, then the

development of synthetic (no natural content) plastics, applications of

plastics today, growing concerns about plastics, and finally the future of

plastics.

I will list my principal sources

at the end.

Introduction

Plastics is a word

that comes from the Greek language, meaning “pliable and easily shaped.” It only recently became a name for a category

of materials called polymers, meaning “of many parts,” and made of long chains

of molecules. Polymers abound in

nature. Cellulose, the material that

makes up the cell walls of plants, is a very common natural polymer.

While we think of plastic as a 20th-century material, natural plastics such as animal horn, tortoiseshell, amber, rubber, and shellac have been worked with since antiquity. In 1600 BC, Mesoamericans used natural rubber for balls, and figurines. The first written record of shellac appeared in about 1000 BC. In the Middle Ages, Europeans used treated cow horns as translucent material for windows. The Japanese and Chinese used ox horns for the same purpose, as well as for shades of oil lamps. Animal horns, malleable when heated, were used for many purposes and products, from medallions to cutlery. The comb-making industry was one of the biggest applications of animal horns in the 19th century.

19th-century comb with two circular grips, made in India from incised and carved decoration animal horn.

Over the

last two centuries, humans have learned how to make synthetic polymers,

sometimes using natural substances like cellulose, but more often using the

plentiful carbon atoms provided by petroleum and other fossil fuels. The long molecule chains of synthetic

polymers are arranged in repeating units, often much longer than those found in

nature. It is the length of these chains

and the patterns in which they are arrayed that make polymers strong,

lightweight, and flexible.

These

properties make synthetic polymers exceptionally useful, and since we learned

how to create and manipulate them, polymers have become an essential part of

our lives.

Their plasticity makes it possible for plastics to

be molded, extruded, or pressed into solid objects of

various shapes. This adaptability, plus

a wide range of other properties, such as being lightweight, durable, flexible,

and inexpensive to produce, has led to its widespread use.

The world's

first fully synthetic plastic was Bakelite, invented in New York in

1907, by Leo Baekeland, who coined the term "plastics.” Dozens of different types of plastics are

produced today, such as polyethylene, which is widely used

in product packaging, and polyvinyl chloride (PVC), used

in construction and pipes because of its strength and durability.

In

developed economies, about a third of plastic is used in packaging and roughly

the same in buildings in applications such as piping, plumbing, or vinyl

siding. Other uses include automobiles

(up to 20% plastic), furniture, and toys.

Plastics pervade all aspects of society.

We sleep on plastic-filled pillows, clean our teeth with plastic

toothbrushes, type on plastic keyboards, drink and eat food from plastic

containers; it’s impossible to go through a day without encountering plastic of

some kind.

But as we are becoming increasingly aware, our widespread adoption of plastics has caused widespread environmental problems, due to their slow decomposition rate in natural ecosystems. Most plastic produced has not been reused, or is incapable of reuse, either being captured in landfills or persisting in the environment as plastic pollution. Plastic pollutes our landscapes, oceans, air, and bodies, and remains a contentious issue for our future.

The First Semi-Synthetic Plastics

By the middle of the 19th

century, in the wake of industrialized goods production, some animal-derived

materials had become increasingly scarce.

Elephants were facing extinction if demand for their ivory, used in

items from piano keys to billiard balls, continued. The same fate awaited some species of turtle,

whose shell was harnessed for combs.

Inventors attempted to tackle this

environmental and economic problem, with many patents for new materials based

on natural substances (semi-synthetic plastics).

One of the earliest was cellulose

nitrate - cotton fibers dissolved in nitric and sulfuric acids, then mixed with

vegetable oil. Its inventor, English chemist Alexander Parkes,

patented this new material in 1862 as Parkesine. Considered the first man-made plastic,

it was a cheap and colorful substitute for ivory or tortoiseshell, but

the manufacturing process was complex and costly.

English chemist Alexander Parkes produced the first man-made plastic.

In 1869, American inventor John Wesley

Hyatt simplified the manufacturing process for a similar compound, blending

camphor with nitrocellulose, and produced a hard, moldable substance he dubbed celluloid,

a plastic that could be crafted into a variety of shapes and made to imitate

natural substances like tortoiseshell, horn, linen, and ivory. In addition to creating this new material, he developed the

necessary machinery for working it. Hyatt

and his brother began producing celluloid in quantity in 1871, marketing it as

a substitute for natural materials like ivory and tortoiseshell, and created and

sold objects like dental plates, jewelry, combs, mirrors, toys, baby rattles, and

even shirt collars.

American John Wesley Hyatt invented celluloid plastic and simplified the manufacturing process for similar compounds

Undoubtedly, celluloid’s greatest

cultural application was movie film.

Celluloid plastic was used in the first movie films

Development of Synthetic Plastics

In 1907, Belgian-American chemist Leo

Baekeland invented Bakelite, the first fully synthetic plastic, meaning

it contained no molecules found in nature.

Baekeland had been searching for a synthetic substitute for shellac, a

natural electrical insulator, to meet the needs of the rapidly electrifying

United States. His invention combined

two chemicals - formaldehyde and phenol - under heat and pressure.

Belgian-American chemist Leo Baekeland invented Bakelite, the first fully synthetic plastic.

Bakelite was not only a good insulator;

it was also durable, heat resistant, and, unlike celluloid, ideally suited for

mechanical mass production. Marketed as

“the material of a thousand uses,” Bakelite could be shaped or molded into

almost anything, providing endless possibilities.

Bakelite telephone made in the 1930s.

Hyatt’s and Baekeland’s successes led

major chemical companies to invest in research and development of new polymers,

and new plastics soon joined celluloid and Bakelite.

In the early decades of the 20th

century, the petroleum and chemical industries began to form alliances into

companies like Dow Chemicals, ExxonMobil, DuPont, and BASF - driven by the

desire to make use of waste material from processing crude oil and natural

gas. These companies are still the major

producers of raw materials for the plastics industry today.

One of the most abundant of these byproduct

waste materials was ethylene gas. In

1933, a team at the British firm of Imperial Chemical Industries (ICI), was

attempting to combine ethylene and benzaldehyde under great pressure and

heat. The experiment failed. Instead, due to a leak of oxygen into the

vessel, they found a white waxy substance in a reaction tube. This was found to be a polymer of

ethylene. Now the world’s most abundant

plastic, polyethylene was a wonder material: strong, flexible, and heat-resistant.

Polyethylene’s first application was

insulating radar cabling during the Second World War, but consumer products

soon followed, from the plastic shopping bag and Tupperware to

artificial hip and knee joints.

ICI’s U.S. rival DuPont had a series

of plastic successes in the 1930s, notably Nylon and Teflon. Nylon, invented by Wallace Carothers

in 1935 as a synthetic silk, was used during the war for parachutes, ropes,

body armor, helmet liners, and more. Nylon

stockings were an immediate worldwide sensation. Another

plastic, plexiglass, provided an alternative to glass for aircraft

windows.

Two pairs of Triumph nylon stockings from the 1950s.

A Time magazine

article noted that because of the war, “plastics have been turned to new uses

and the adaptability of plastics demonstrated all over again.” During World War II plastic production in the

United States increased by 300%.

The surge in plastic production

continued after the war ended. After

experiencing the Great Depression and then World War II, Americans were ready

to spend again, and much of what they bought was made of plastic. According to author Susan Freinkel, in her

2011 book Plastic: A Toxic Love Story,

“In product after product, market after market, plastics challenged traditional

materials and won, taking the place of steel in cars, paper and glass in

packaging, and wood in furniture.” The

possibilities of plastics gave some observers an almost utopian vision of a

future with abundant material wealth thanks to an inexpensive, safe, sanitary

substance that could be shaped by humans to their every whim.

Applications for Plastics

Plastics are used today for an incredible variety of products

in the modern world. As the

chart below shows, the amount of plastic produced in the world every year has

increased explosively in just a human lifetime. Some of the most common uses of

plastic listed after the chart.

Plastics production from 2 million tons in 1950 to over 390 million tons in 2021. The expectation is that the production will increase to about 1480 million tons by 2050.

Application

of plastics today include:

1. Packaging:

Ideal

material to use for product packaging.

Plastics are adaptable, hygienic, light, flexible, and durable. Packaging is thus responsible for most of the

plastics used globally, coming in the form of vending packaging, baby products,

protective packaging, containers, bottles, drums, trays, boxes, cups, shopping bags,

and much more.

2. Construction: Economically appealing thanks to their outstanding

strength-to-weight ratio, cost effectiveness, durability, low maintenance

requirements, and corrosion resistance.

Plastics are used in, among other things, water supply and sewage pipes,

insulation, roofing materials, windows., gutters, and doors.

3. Electronics: Can protect electronic components and

allow for easy assembly because they are non-conductive. This is why you find plastic in computers,

phones, televisions, household appliances, insulation on wires, and

communication equipment.

4. Transportation: Used in various parts of automobiles, including

dashboards, bumpers, engine parts, headlights, wing mirrors, interior panels,

and upholstery. Since plastics are both

lightweight and durable, they reduce the vehicle’s weight and improve fuel

efficiency. The same goes for other

types of transportation including airplanes, rockets, trains, and boats.

5. Clothing: Used for textiles after conversion into synthetic

fibers and fabrics. Modern clothing and

upholstery commonly include plastics, including stretchable fabrics and

fleece. For example, polyester,

which is a flexible, water-resistant synthetic fiber, is used for making

blouses, sweaters, jackets, and underwear.

Plastics are also used in space suits, protective vests, and safety

helmets.

6. Medical Devices: Application include, but not limited to,

disposable syringes, IV and blood bags, prosthetic limbs, implantable devices,

dialysis machines, heart valves, tubing, and wound dressing. Medical-grade plastics are sterile and

biocompatible and can be easily molded into complex shapes. Plus, they’re often less expensive than

traditional medical materials.

7. Furniture:

Applications

include bedding, upholstery, household furniture, and carpets.

8. Energy Generation: Used in wind turbines, solar panels,

and ocean wave energy conversion panels

9. Consumer Goods:

Often

used in the production of toys because they can be molded into various shapes

and colors. Plastic toys are durable and lightweight, so they withstand wear

and tear. Other consumer goods include

tableware (glasses, spoons, forks, etc.) and toothbrushes.

Following World War II, along with the

tremendous increase in the use of plastics and the explosion of plastics

production shown above, there have been growing concerns.

The chemical properties that have

made plastic an incredibly useful and durable material also make it difficult

to dispose of, with some types taking thousands - even tens of thousands - of

years to degrade in landfills.

The degradation itself is an even

bigger environmental issue, as the breaking down of plastics into microscopic

particles pollutes our ocean, air, and ecosystems. The health implications of

microplastic deposits in our bodies are not yet fully known.

And since the modern plastics industry

relies on fossil fuels for its raw material, the production of plastic has an

impact on climate change, contributing to global C02 production.

Plastic debris in the oceans was first

observed in the 1960s, a decade in which Americans became increasingly aware of

environmental problems. Rachel Carson’s

1962 book, Silent Spring, exposed the dangers

of chemical pesticides. In 1969, a major

oil spill occurred off the California coast and the polluted Cuyahoga River in

Ohio caught fire, raising concerns about pollution. As awareness about environmental issues

spread, the persistence of plastic waste began to trouble observers.

Plastic’s reputation fell further in

the 1970s and 1980s as anxiety about waste increased. The

ultimate symbol of the problem of plastic waste is the Great Pacific Garbage

Patch, which has often been described as a swirl of plastic garbage the size of

Texas floating in the Pacific Ocean.

Plastic rubbish in the ocean near Roatan, an island off the coast of Honduras.

It was the plastics industry that

offered recycling as a solution. In the

1980s, the plastics industry led an influential drive encouraging

municipalities to collect and process recyclable materials as part of their

waste-management systems. However,

recycling is far from perfect, and most plastics still end up in landfills or

in the environment. Grocery-store

plastic bags have become a target for activists looking to ban one-use,

disposable plastics, and several American cities have already passed bag bans.

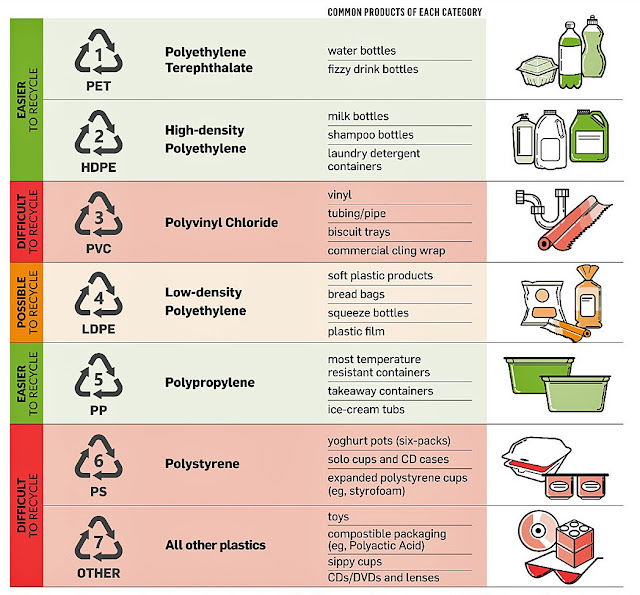

There are a

lot of different types of plastic available today, each with its own unique set

of properties and uses. The most

prominent types of plastic are listed in the chart below, organized by recyclability

category, and showing common plastic products in each category. (These recyclability codes are commonly

printed on today’s plastic products.)

Types of plastic by recyclability code.

Among the worst pollution offenders,

along with polyethylene shopping bags and polystyrene food

containers, are polyethylene terephthalate (PET) drink bottles.

The economics of mass-produced, cheap plastic products have led to a single-use

culture, and today around 500 billion PET bottles are sold every year. This figure is increasing, and many of these

bottles end up in our oceans, degrading into microplastics.

The reputation of plastics suffered

further thanks to a growing concern about the potential threat they pose to

human health. These concerns focus on

the additives (such as bisphenol A, commonly known as BPA, and a

class of chemicals called phthalates) that go into plastics during the

manufacturing process, making them more flexible, durable, and

transparent. Some scientists and members

of the public are concerned about evidence that these chemicals leach out of

plastics and into our food, water, and bodies. In very high doses these

chemicals can disrupt the human endocrine (or hormonal) system. Researchers worry particularly about the

effects of these chemicals on children and what continued accumulation means

for future generations.

Even for containers labeled “safe” for the microwave and

dishwasher, experts caution that heat and plastic don’t mix well. Since heat

helps to break the chemical bonds in plastic, it’s possible that exposure to

high temperatures increases the rate of chemical migration from the container

into the food. Scientists have

documented higher rates of chemical migration even in water bottles left in the sun.

To reduce greenhouse gas emissions,

chemists have researched and developed green plastics, which - like

early semi-synthetic plastics - are derived from natural, biological material

such as corn starch. In 1990, ICI, the

British innovators of polyethylene, developed the first practical biodegradable

plastic, Biopol, which was first used in a Wella shampoo bottle.

These materials are becoming increasingly common in single-use packaging. But not all bioplastics are better in terms of

disposing or recycling.

One of the biggest barriers to plastic

recycling is separation: when different polymers are mixed, the resulting

material does not usually have useful properties. Even two PET items, a drink bottle and cookie

cutter, for example, may have different melting temperatures that produce an

unusable sludge when combined.

At the moment, chemical means of sorting plastics are not economically

viable on a big scale, so it’s down to human sorters to do the job.

The Future of Plastics

Despite growing concerns, plastics are

critical to modern life. Plastics made

possible the development of computers, cell phones, and most of the lifesaving

advances of modern medicine. Lightweight

and good for insulation, plastics help save fossil fuels used in heating and in

transportation. Perhaps most important,

inexpensive plastics raised the standard of living and made material abundance

more readily available. Without

plastics, many possessions that we take for granted might be out of reach for all

but the richest Americans. Replacing

natural materials with plastic has made many of our possessions cheaper,

lighter, safer, and stronger.

Since it’s clear that plastics have a

valuable place in our lives, scientists are attempting to make plastics safer

and more sustainable. Innovators are

developing bioplastics, which are made from plant crops instead of fossil

fuels, to create substances that are more environmentally friendly than

conventional plastics. Others are

working to make plastics that are truly biodegradable. Some innovators are searching for ways to

make recycling more efficient, and they even hope to perfect a process that

converts plastics back into the fossil fuels from which they were derived.

All of us recognize that plastics are

not perfect, but that they are an important and necessary part of our future.

[A]Plastic pollution free world is

not a choice but a commitment to life - a commitment to the next generation.

Amit Ray, Indian author and spiritual master

Sources

My principal sources include:

“Plastic” and “Timeline of plastic development,” en.wikipedia.org; “History and

Future of Plastics,” sciencehistory.org; “The Age of Plastic: From Parkesine to

Pollution,” sciencemuseum.org; “American History Highlights Celluloid and the

Dawn of the Plastic Age,” smithsonianmag.com; “Plastics Applications,”

bpf.co.uk; “Plastic: Definition, Types, Properties, Advantages, and

Disadvantages,” xometry.com; plus, numerous other online sources.

Comments

Post a Comment